China’s Aluminum Die Casting Industry Is Driving a Revolution in the Manufacturing Sector

Introduction

In recent years, China has established itself as a major force in the manufacturing sector, offering a diverse choice of products that are both cost-effective and of a high quality. Die casting in aluminum is a process that has significantly improved the efficiency with which complicated metal components may be manufactured, and China is a world leader in this field. In this article, we will delve into the realm of Die casting China and explore the reasons why it has become a game-changer in the manufacturing industry. China aluminum die casting has become a game-changer in the manufacturing industry for a number of reasons.

Understanding Aluminum Die Casting

What exactly is die casting in aluminum?

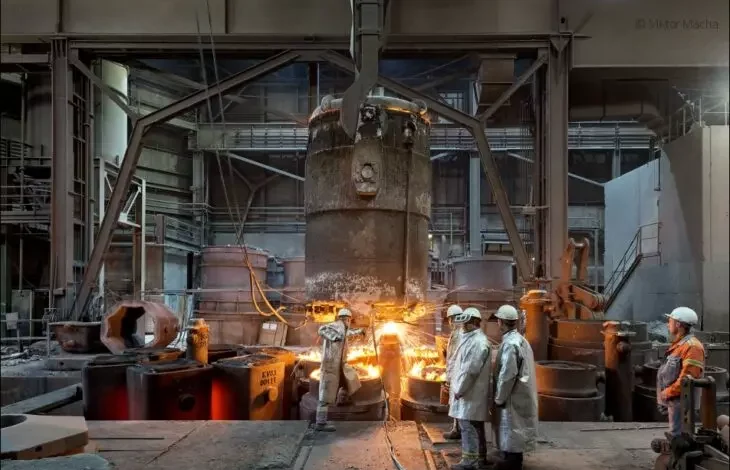

The method of aluminum die casting is a type of manufacturing that involves pumping molten aluminum alloy into a steel mold, also known as a die, under extreme pressure. Utilizing this method, it is possible to manufacture complicated metal parts that have great surface finishes and are sized and shaped to exacting specifications. Die casting in aluminum has found use in a diverse set of industries, ranging from the production of automobile components to those of consumer electronics.

The Many Benefits of Aluminum Die Casting

- Die casting in aluminum has a number of advantages over other methods of production, which is why it is the method of choice for many companies, including the following:

- Aluminum is well-known for having a high strength-to-weight ratio, which makes it perfect for applications that call for components that are lightweight yet are still able to withstand significant stress. Die castings made of aluminum are extremely resilient and can sustain significant amounts of pressure.

- Complex Geometries: The die casting process allows for the manufacture of elaborate designs and complex shapes, both of which are difficult to do with other manufacturing methods. This adaptability paves the way for brand-new avenues of possibility for product development.

- Die casting in aluminum is a procedure that is both highly efficient and successful in terms of cost management. The use of steel molds that can be reused helps to greatly cut down on tooling costs, and the high production rates help to ensure that economies of scale are realized.

- Die cast pieces have a surface finish that is smooth and polished, requiring very little to no post-processing because of the excellent quality of the surface finish. This not only does the finished product seem better, but it also makes it easier to make and takes less time, which cuts down on production costs.

China’s Dominance in the Industry

In order to meet the rising demand for aluminum die castings, China has constructed cutting-edge manufacturing facilities that are replete with cutting-edge machinery and technological advancements. These factories adhere to high quality standards, which guarantees that the produced parts meet or surpass the requirements set forth by the customers.

Developments in the State of Technology

China has achieved tremendous breakthroughs in die casting technology, adopting automation, robotics, and computer-aided design (CAD) software to expedite the manufacturing process. These advancements have allowed the country to produce more with less. The implementation of technology in this manner results in improved precision, decreased mistake rates, and enhanced operational efficacy.

Skilled Workforce

China is home to a labor population that is incredibly experienced and skilled, giving the country the ability to successfully complete difficult die casting projects. Chinese technicians and engineers play a significant part in guaranteeing the successful implementation of aluminum die casting due to their extensive expertise as well as their profound awareness of the complexities involved in the process.

Quality Assurance Procedures and Accreditations

China has adopted stringent quality control procedures throughout the entire process of China aluminum die casting in order to keep up with the high quality requirements that have been set. It is common practice among Chinese manufacturers to comply to international quality certifications such as ISO 9001, ISO 14001, and IATF 16949. This helps ensure that the items they produce are up to par with international quality standards.

Pricing that is competitive

Pricing that is far lower than its competitors is one of the primary reasons China is the market leader in aluminum die casting. Chinese manufacturers are able to provide cost-effective solutions without sacrificing quality thanks to the easy availability of low-cost raw materials and efficient production techniques. Because of this advantage, corporations from all over the world that are looking to reduce the amount they spend on manufacturing have shown interest in the area.

Conclusion

Because of China’s unparalleled skill in aluminum die casting, the country has quickly risen to the top of the world’s manufacturing industry. China has been the go-to location for firms that are searching for high-quality and cost-effective aluminum die castings due to the combination of modern technology, trained workforce, tight quality control, and low pricing. Companies have the potential to gain considerable operational economies, product breakthroughs, and a competitive edge in their particular markets by capitalizing on the benefits given by aluminum die casting in China.

For more information visit our website.